The conversion of biomass into reusable fuel has become mainstream in recent years. The need for utilizing already existing materials that can become burnable fuel is of great prominence. There are biomass to machines that are able to convert biomass through the carbonization process using machines that are very inexpensive. The technology has advanced greatly in recent years, allowing even small businesses to utilize what is available. If you would like to obtain a biomass to charcoal machine for your business, this is how you can find one quickly.

How Is Biomass Converted Into Fuel?

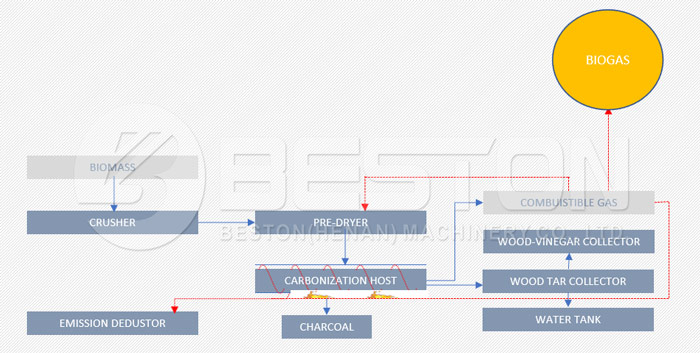

Biomass can be converted into fuel very easily. It goes through a process called pyrolysis. It is heated to a temperature where the material will break down. What is left is liquid and solid fuel. That which is solid is called charcoal. This is sold to people and businesses around the world. The liquid material can be used as a lubricant or may even be bought by cosmetic companies. It does not burn because the oxygen is not in the reactor when it is heating up. If you have a lot of biomass, you will definitely want to find a company that can sell you a charcoal making machine in Cote d’Ivoire.

How To Find Companies That Sell These Products?

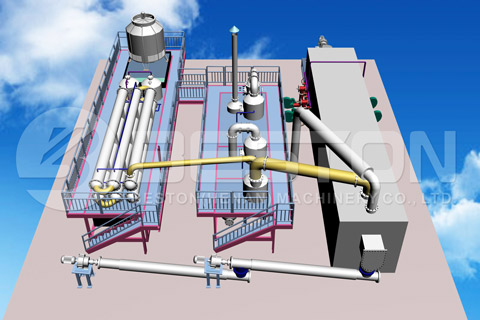

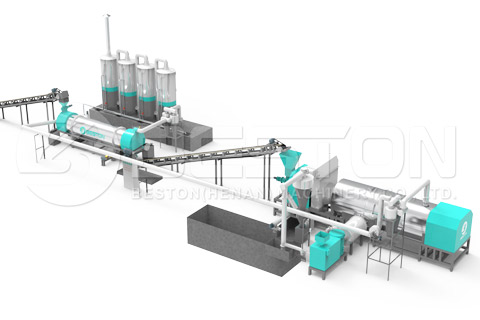

Locating businesses that sell these products is easier than ever before. Part of the reason is that more companies are offering them for sale. It is also easier to find them because of the web. You can find company websites that will showcase several of their batch charcoal making machine. You do have to evaluate them to make sure that they are large enough to handle all of the biomass you need to process. Other things to consider include the type of energy that it uses to power the system. Also consider the different types of biomass that can be processed. All of this information can help you make the right decision when obtaining one from these businesses. View more details from this video.

Different Ways To Evaluate These Biomass to Charcoal Machines

There are several things to consider. First of all, you need to think about its size. The larger the unit is, the more fuel that can produce. Consider the type of customers that you will have for this business. Charcoal can be sold to regular people, different industries, and even the agricultural market. The machines should also be the right size for your facility. You need to have enough room to house them. Consider the cost of shipping and how long it will take to arrive. These are all factors that must be considered before making your purchase.

Getting a biomass to charcoal machine can be done in a matter of hours. You need to take the time to find the companies and eventually evaluate them based upon production and cost. Once they are sent to you, they should take no longer than a few days to set up. Once they are fully functional, you will never have to worry about access biomass at your facility. It will simply be converted into a marketable product that can help your business grow. When you wanna get a good machine, click https://bestonmachinery.com/charcoal-manufacturing-machine/.