The continuous waste tyre pyrolysis plant comes equipped with an automatic discharging and feeding system, that feeds materials on 1 side and discharges slag on another side. This continuous waste tyre pyrolysis plant is capable of disposing of 20 to 24 tons of waste tyres daily and can operate continuously (24 hours a day).

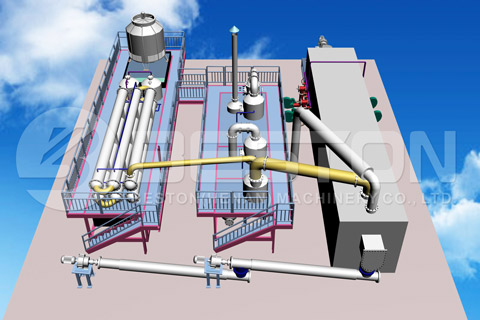

These plants are made of 11 parts which include:

– Horizontal moving pyrolysis reactor

– Oil gas filter

– Hot-air circulation heating-system

– Spray cooling system

– Spray dedusting system

– Fire-retardant damper (secondary)

– Feeder system

– Oil gas recycling-system

– Temperature and pressure multipoint-monitoring system

– Discharging system

– Central electronic-control system

Each of these parts has been manufactured with advanced technologies and high-quality materials. These plants are also required to pass CE, SGS, and ISO certificates, along with high-quality guarantees.

When using pyrolysis plants in order to dispose of waste tyres, these pre-treated tyres are first conveyed to a horizontal moving pyrolysis reactor directly through an automatic feeder. Inside the reactor, the waste tyres undergo pyrolysis reactions due to the actions of a catalyst. At the end of the pyrolysis process, the materials produced include steel wire, carbon black, and fuel oil.

The fuel oil is a product that is used widely for industries like boiler, iron, and steel factories, chemical, power, or ceramics industries, along with restaurants and hotels. This fuel oil is also used in generators to produce electricity.

The carbon black is often used in the construction of bricks that are made with clay. It is also used as a type of fuel.

The steel wire is directly recycled or sold in order to produce new types of steel products.

The Benefits Of The Continuous Waste Tyre Pyrolysis Plant

In addition to offering a way to reduce and recycle tyre waste that used to end up in landfills, the waste tyre pyrolysis plants are associated with a number of advantages. These include the following:

– High capacity, with the ability to process a minimum of 10 tons of waste every day, or a maximum of 100 tons of waste daily.

– These plants are fully automatic and feature a continuous discharge and feeding system.

– The Continuous Waste Tyre Pyrolysis Plant features a computer-control or PLC system which helps to save on labor costs.

– The Multiple Reactor design achieves full pyrolysis that results in high oil rates.

– The indirect heating method prolongs the reactor’s life-span and usage.

Similar to the batch-type pyrolysis plants, this machinery is also suitable for waste plastics. This web offers good machine https://enboard.co/bestonmachinerychina/.

– Collection of waste tyres

– Removing the steel wire out of the waste tyres

– Shred tyres. This process shreds the waste tyres into 3 to 5 cm pieces to accommodate easy feeding

– Continuous pyrolysis process. The shredded tires are then fed into the reactor system where they are pyrolyzed into gas and oil

– The residues which are known as carbon black is pushed out by the continuous feeding of the tyres through a discharge system. View more info about this process https://tyrepyrolysisplants.net/tyre-recycling-process.html.