When it comes to running a profitable garage recycling business, choosing a great solid waste treatment plant is vital. There are many different setups that you can implement in a recycling facility using a range of different machines, including MSW sorters. The sorting efficiency rate will depend on the model of municipal solid waste sorting machine you buy. Top-of-the-range models can accurately sort just about every type of waste into processable material categories, such as plastics, metals, construction waste, organic matter, combustibles, etc.

One of the main reason why running a solid waste processing plant can be so profitable is because countries are having to deal with increasing quantities of trash every year. Governing bodies often provide waste management facilities with generous grants and subsidies to reduce the amount of material they send to landfill sites. With the right MSW treatment plant design and machinery, it is possible to recycle over 85% of a city’s trash.

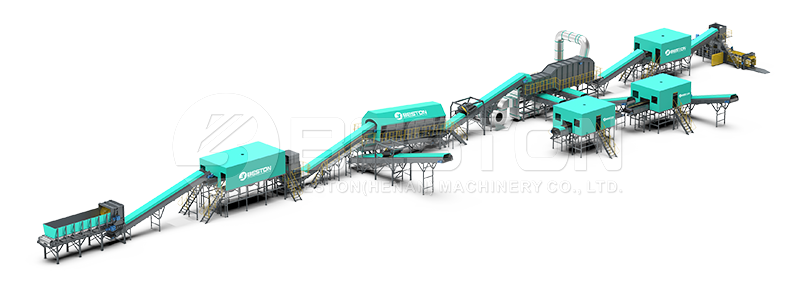

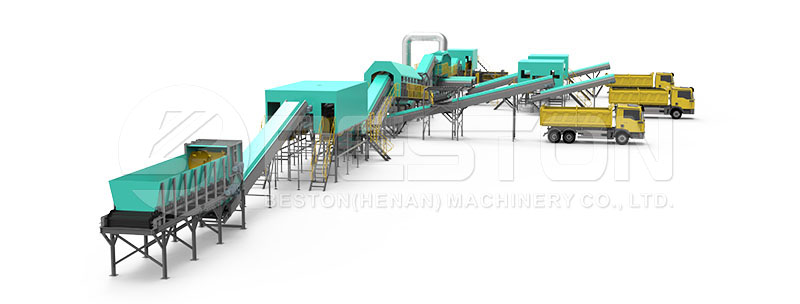

A garbage recycling plant is comprised of lots of separate components, which can operate independently and in unison. With a fully automatic trash sorter, all of the complex modules work in synchronicity to separate, processes and pack all types of mixed waste. MSW sorters with the most advanced engineering technology can process hundreds of tons of garbage a day.

When mixed waste first enters a typical sorting facility, it is automatically (or manually) loaded onto a conveyor belt and moved through air sorters. The mixed waste is then transported over magnetic separators, which remove any magnetic metal materials. As the mixed garbage continues its journey through the waste treatment plant, it continues to be separated into dozens of recyclable material categories including plastic, glass, organic matter, rubber, combustibles and more. All materials that can’t be recycled collect at the last station in a plant for disposal.

Once the mixed waste has been sorted into different material categories, further processes are carried out to convert the materials into valuable commodities. Plastics and rubber, for example, can be processed in a waste pyrolysis plant and turned into fuel oil and combustible gas. Meanwhile, the organic matter can be converted into fertilizer or biogas. To convert organic matter into biogas, a fermentation process is needed. Combustibles, such as cardboard, textile fabric, and fibers can be turned into fuel blocks using carbonization. All sort of profitable end products can be manufactured using the best solid waste treatment plant machinery.

The great thing about modern municipal waste sorting plants is that they don’t emit any atmospheric pollution. Odor removers, advanced smoke filters, and atomization systems are incorporated into plant designs to ensure zero-emissions and a safe working environment for manual workers.

There are hundreds of different models for MSW sorting machines for sale. To benefit from the best prices, you need to compare the cost of solid waste separation equipment from multiple suppliers, including overseas suppliers. In most cases, you are likely to find the cheapest machines from manufacturers and vendors in China. Just make sure you remember to factor in currency conversion fees and import fees.