In the quest for sustainable solutions and environmental stewardship, the artistry of Biochar Production emerges as a transformative force, weaving carbon-rich wonders from organic residues. In this exploration, we delve into the intricate world of biochar, where ancient wisdom meets modern innovation to create a carbonaceous marvel.

The Essence of Biochar Production

At its core, Biochar Production is a profound synthesis of ancient knowledge and cutting-edge technology. This process involves the conversion of biomass, such as agricultural residues or woody materials, into biochar through pyrolysis—an oxygen-limited thermal decomposition. More information on biochar production equipment.

The Alchemical Dance of Pyrolysis

Within the confines of the pyrolysis chamber, an alchemical dance unfolds. Biomass, subjected to controlled heat in the absence of oxygen, undergoes a metamorphosis. This controlled thermal degradation gives rise to biochar, a stable form of carbon that bears the imprints of its organic origins.

As the temperature ascends, volatile compounds are liberated, leaving behind a carbon-rich residue—the biochar. The intricate dance of pyrolysis not only transforms biomass into a valuable carbon sink but also yields bioenergy-rich gases and liquids, offering a trifecta of environmental benefits.

Key Components in the Spotlight

-

Pyrolysis Reactor

Central to the symphony of biochar production is the pyrolysis reactor, a crucible of controlled thermal dynamics. This reactor orchestrates the dance of biomass to biochar, ensuring optimal conditions for the carbonization process.

-

Condensation System

The condensation system plays the role of a vigilant custodian, capturing and condensing the bioenergy-rich gases liberated during pyrolysis. This not only harnesses additional energy but also prevents the release of potentially harmful substances into the atmosphere.

-

Biochar Activation Chamber

For those seeking a higher echelon of biochar functionality, the activation chamber comes into play. Activation involves further processing of biochar to enhance its surface area and adsorption capabilities, turning it into a versatile tool for soil improvement and environmental remediation. See the biochar pyrolysis equipment here.

-

Gas Cleaning Unit

Ensuring purity in the by-products, the gas cleaning unit meticulously removes impurities from the liberated gases. This step safeguards the quality of bioenergy-rich gases and aligns with the ecological integrity of the entire process.

Keywords in the Spotlight

As we navigate the biochar production landscape, several keywords enrich our lexicon and deepen our understanding:

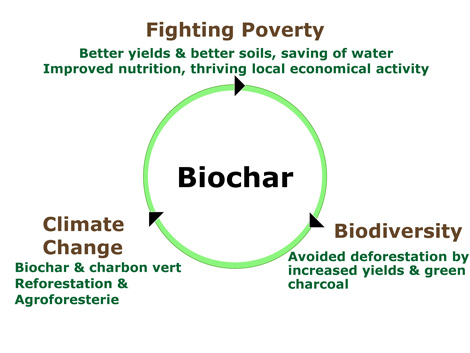

- Carbon Sequestration: Biochar, a carbon-rich residue, stands as a formidable ally in the battle against climate change, sequestering carbon and preventing its release into the atmosphere.

- Soil Amendment: The application of biochar as a soil amendment rejuvenates agricultural landscapes, enhancing water retention, nutrient availability, and overall soil fertility.

- Pyrolysis Kinetics: The study of pyrolysis kinetics delves into the intricate time-temperature relationships governing the transformation of biomass into biochar, a science that underpins the efficiency of the entire process.

- Agronomic Benefits: The agronomic benefits of biochar are manifold, spanning improved crop yields, increased water-use efficiency, and resilience against soil-borne pathogens.

Unraveling the Applications

The versatility of biochar extends far beyond its role as a carbon sink. Its applications resonate across diverse fields, offering sustainable solutions to pressing environmental challenges. Check the charcoal making machine here.

Soil Enrichment and Carbon Farming

Biochar’s foray into agriculture is marked by its role as a soil conditioner. Its porous structure provides a habitat for beneficial microorganisms, enhances nutrient retention, and fosters a resilient soil ecosystem. Carbon farming, empowered by biochar, becomes a beacon of sustainable agriculture.

Waste Valorization

Biochar production transforms organic waste into a valuable resource. Agricultural residues, forestry by-products, and even certain types of municipal waste find new purpose through this alchemical process, reducing the burden on landfills and contributing to a circular economy.

Environmental Remediation

Activated biochar emerges as a potent tool in environmental remediation. Its adsorption capabilities make it an effective agent for removing pollutants from air and water, showcasing its potential in mitigating the impacts of industrial activities.

A Glimpse into the Future

As biochar production continues to evolve, innovations in feedstock selection, pyrolysis technology, and activation methodologies promise an even brighter future. The biochar landscape awaits further revelations, with potential applications ranging from carbon-negative construction materials to sustainable energy storage. Visit the Beston Group here.

In conclusion, biochar production stands at the crossroads of tradition and innovation, offering a sustainable solution rooted in ancient wisdom and propelled by modern science. The alchemical transformation of biomass into biochar embodies a harmonious blend of ecological benefits, paving the way for a resilient and regenerative future. In the realm of environmental sustainability, biochar production stands tall—an alchemical testament to the transformative power of carbonaceous wonders.