When you cultivate rice, and it is harvested, you will have a large amount of rice husks that need to be removed. For some, this will be a form of fertilizer. Compost piles will be set up for this purpose. However, there is an easier way to dispose of this material which can also be slightly more profitable. This is through using a charcoal making machine. Often referred to as a pyrolysis machine, it can convert the rice husks into charcoal. If you do have an abundance of rice husks on an annual basis, this would be a great way to use them in a positive way. To get the very best machine available, this is how you can locate a rice husk charcoal making machine that will be ideal for your business.

How Does It Convert Rice Husks Into Charcoal?

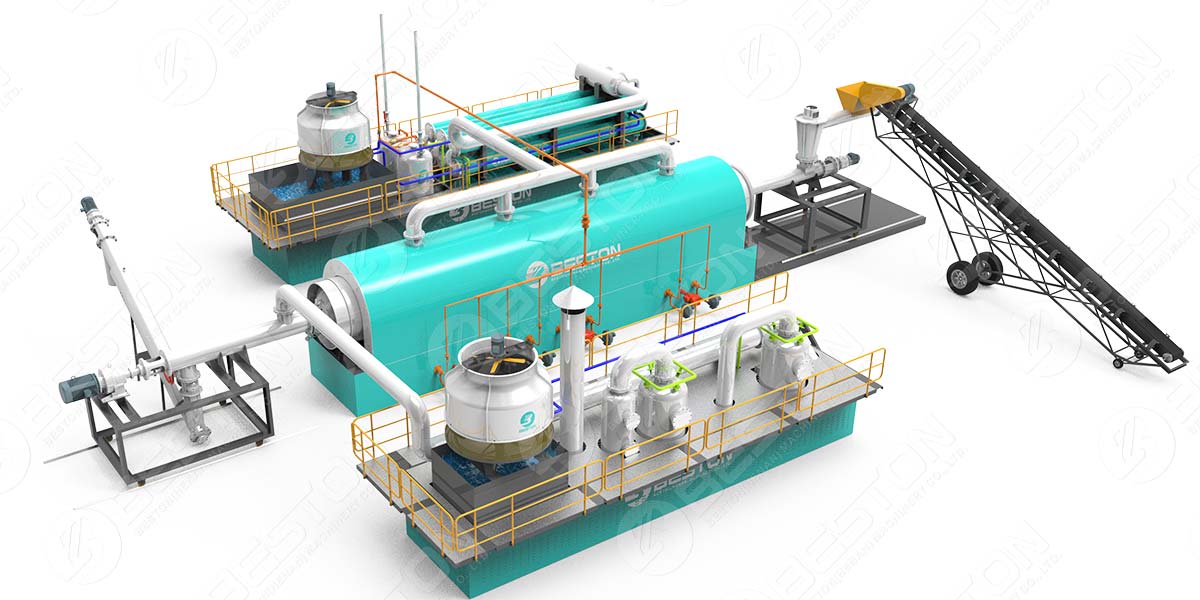

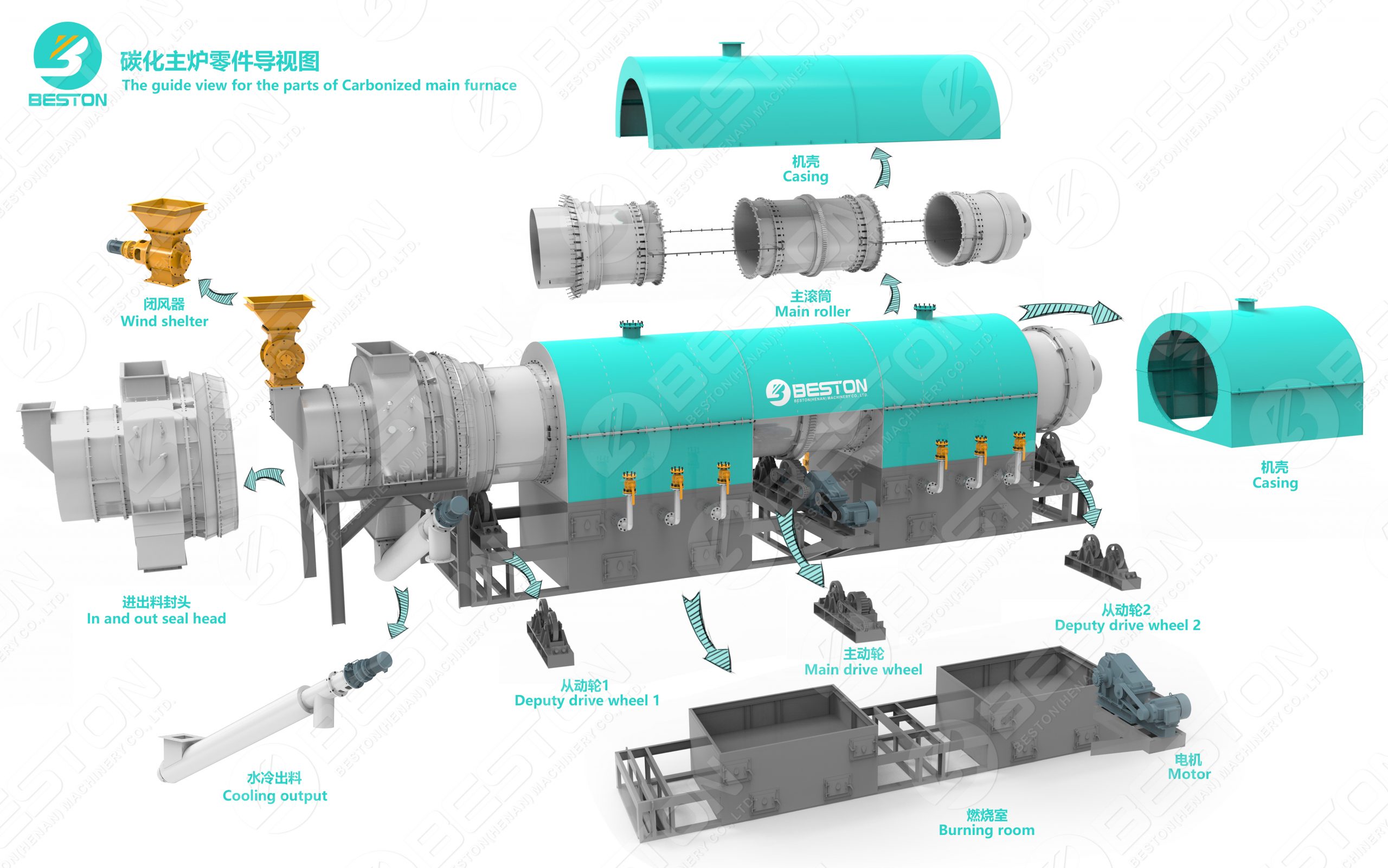

One of the benefits of using rice husks for this particular purpose is that no augmentation of this material is needed. They are already extremely small, and can easily be placed inside of the pyrolysis chamber. Once inside, the biochar machine for sale can then be turned on. It will evacuate all of the oxygen within the chamber before the heat is added. As the temperature rises, the material will begin to change. Combustion will be avoided due to the lack of oxygen inside. What will remain will be charcoal that can be sold or used.

How To Find Companies That Market These Products

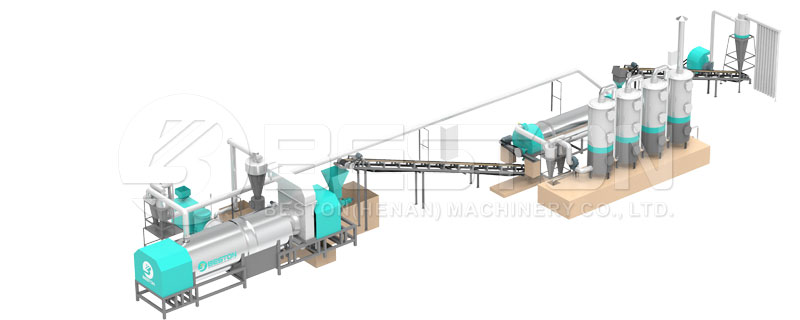

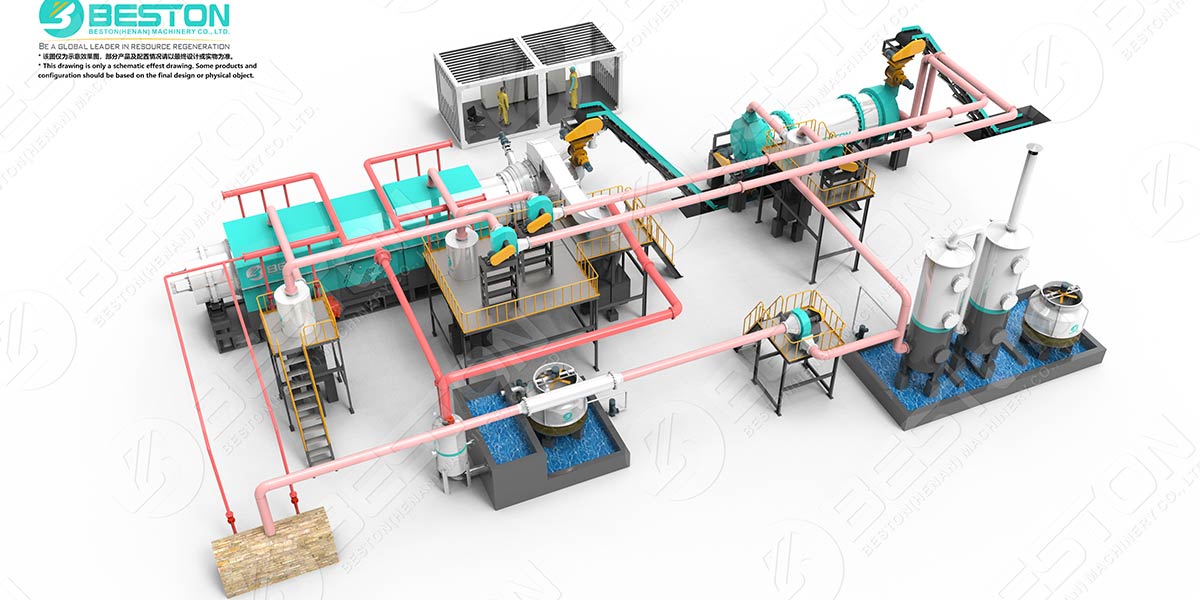

Businesses that produce these products are likely also making pyrolysis machines and plants that can convert different materials. Examples of this would be pyrolysis plants that can convert thousands of tons of plastic and rubber tires, converting them into charcoal as well. If you need to have this set up at a particular location where you are harvesting rice, you can set one up on a permanent basis. However, if you have multiple locations where you are harvesting, portable units would likely be the best choice for your business.

Ways To Find The Right Company

The best companies can be easily found by searching for industrial businesses that specialize in this industry. Charcoal making machines come in all different sizes. You may want to specifically look for one that is designed to convert rice husks into charcoal. The size of the charcoal making machine, its availability, and the price that you will pay are factors that you must consider. Also consider the delivery time. If you are ordering this from outside of its country of origin, it could take quite a while for it to arrive. All of this information can be found online, allowing you to evaluate each company and subsequently call them to place your order.

Rice husk charcoal making machines have become very popular. There are so many locations around the world where rice is harvested regularly. If you have not found one of these companies before, it will be easy to do. You may even order from them many times. When you have the capability of converting rice husks into burnable fuel, you will have a way of generating more revenue for your business. Start looking today for the most reliable companies that are manufacturing rice husk biochar production equipment that you can obtain.