What is pyrolysis? This term describes the simultaneous chemical and physical reactions that occur in organic substances when they’re exposed to extremely high temperatures. In general, a continuous waste tyre pyrolysis plant is a specially made tire recycling equipment that implements the pyrolysis technology to recycle waste tires into various products such as fuel oil and carbon black.

With these machines, you can create fuel oil from all kinds of waste plastics. Remember, this is all performed in an environmentally friendly way. That also means they are essential in handling the waste plastic disposal issue.

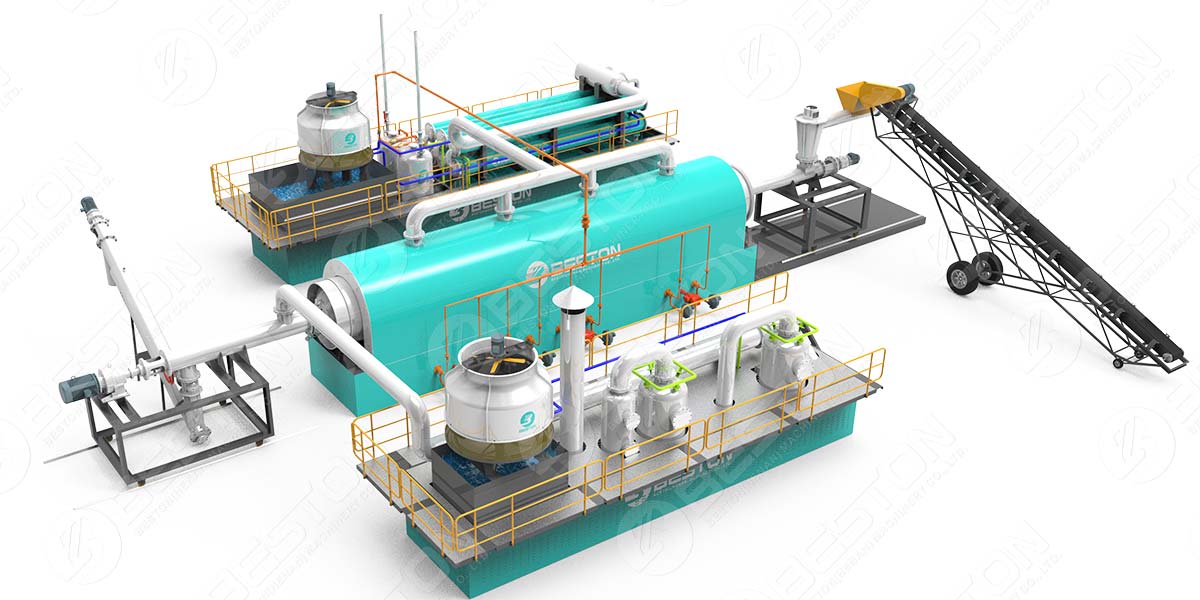

Typically, a fully continuous pyrolysis machine implements a fully automatic procedure that might be remotely controlled via a Programmable Logic Controller system or a computer. Because of the continuous or automated feeding and discharge system, this machine can constantly maintain the optimum performance of a pyrolysis system.

Keep reading and learn about the working procedure of this continuous pyrolysis machine, and some of the benefits it offers. More information on pyrolysis plant UK here.

The Working Process

– The process begins by shredding the available plastic materials into fine plastic granules with the help of a plastic crusher. Afterward, these granules are fed into this fully continuous tire pyrolysis machine via the machine’s feeding door.

– The feeding door of this machine typically comes with an in-built screw to allow easy conveying of the earlier small plastic granules into the plant’s first reactor. The plastic materials available can then be decomposed in extremely high-temperature conditions via its first reactor, to its second…, until they have all undergone pyrolysis. Next, the carbon black powder produced will be released into a carbon black tank.

– Water circulation will help in cooling all the oil gas produced. The additional pyrolysis gas will simultaneously undergo recycling since they’re sent to the burners where the heating procedure is repeated. A fully continuous tire pyrolysis equipment consists of a water circulation system, and a pyrolysis gas recycling system. All these generally help you to save water and lower energy bills. You will ultimately maximize your returns. Get oil sludge pyrolysis plant here.

Benefits of a Fully Continuous Tire Pyrolysis Plant

– High oil output & large volume. Because the system allows continuous feeding and discharging – and has multiple reactor designs – this machine can produce a huge volume of waste tires daily. And since it provides full pyrolysis of waste tires, this plant can deliver high oil output.

– Reduced labor cost. As previously stated, this equipment is controlled by a specially made PLC system and allows automatic feeding, and has a discharge system. Therefore, you’ll only require one to several employees to operate. Its continuous process might also help to save time and energy.

– Extended working life. With the continuous pyrolysis oil plant, indirect hot air heating is required for heating the reactors. Therefore, the reactor won’t be much damaged, which allows a long usage life.

– Enables internal rotating for optimum constant operation. When it comes to the external rotating system, you’ll require to keep changing the machine’s seal material. Fortunately, the fully continuous pyrolysis equipment implements the internal rotating technique. Therefore, you don’t need to change the sealing.