The wood charcoal making machine, also known as the biomass carbonization machine, is used to convert wood chips, tree barks, bamboo chips, tree branches, and agricultural waste into biomass charcoal through a process known as carbonization. This is the process of converting organic matter including plant materials and animal substances into carbon by heating it in the absence of oxygen. This is an effective way of producing high-quality and eco-friendly charcoal which can be used for a wide range of purposes.

By investing in a wood charcoal making machine, you stand to gain significant profits by selling the products you make. After all, there is a high demand for charcoal, and the raw materials are easily accessible. What better business opportunity than turning waste into a product with a high economic value and a multitude of uses. What’s more, the machine also gives you biogas, tar, and wood vinegar as by-products. All of these products offer value to the investor.

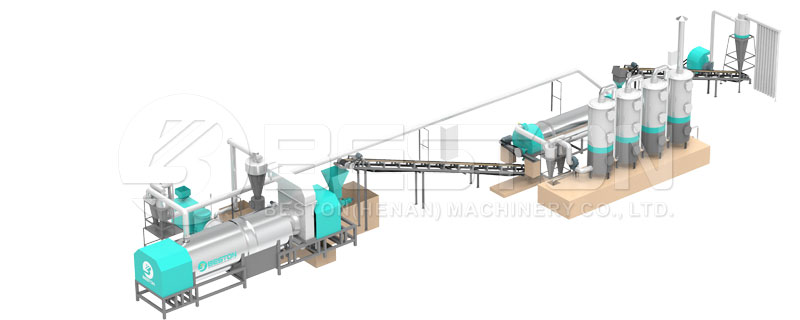

The Wood Charcoal Making Process

The wood charcoal production process designed by Beston Group China basically involves 3 steps: crushing and drying, carbonization and discharge, production of the combustible gas, and re-use of gas.

But first, there are some important requirements that should be met when it comes to raw materials.

i) The wood waste materials should not contain moisture content exceeding 15%. If your raw materials have a higher moisture content, you need to set up a drying system.

ii) The materials should not exceed 20 mm in size. If they don’t meet this standard, you will need to set up a crusher.

With that being said, here’s what goes on in the biochar production units:

Crushing and drying: As indicated above, the first step is to ensure that your wood materials meet the expected standards:a moisture content below 15% and size not exceeding 20 mm. The materials are first crushed and dried in the drying system.

Carbonization and Discharge: Before any wood chips are fed into the carbonization furnace, it is first pre-heated for a period of one hour. The dried wood materials move onto the feeder through a conveyor belt and are then fed into the carbonization furnace. After about 20 minutes, the charcoal is discharged.

Production of the Combustible Gas

The production of the combustible gas begins after 10 minutes of feeding the wood materials. The gas then moves into the cyclone dust removal system and spray dust collector where it is cleaned. It then enters the condenser which separates the wood vinegar and tar. The gas that remains is pushed out of the carbonization furnace by the induced draft fan.

Recycling the Combustible Gas

The ejected combustible gas can be redirected and used to heat the carbonization reactor.

The wood charcoal making machine is designed to continuously carbonize wood waste materials. The wood charcoal making machine can discharge the end products while it is still being fed increasing the overall efficiency of charcoal production.

The Beston charcoal making machine is definitely a handy piece of equipment for anyone looking to venture into the biochar selling business.