The growing emphasis on sustainability has brought biomass processing technologies to the forefront of eco-friendly initiatives. One particularly promising application is the conversion of agricultural residues, such as straw, into biochar using a biomass pyrolysis plant. This process offers a range of environmental, agricultural, and economic benefits, making it an attractive solution for addressing waste management, improving soil quality, and reducing carbon emissions.

Environmental Impact and Waste Management

Straw, an abundant by-product of cereal crops, is often burned as a means of disposal, especially after harvest. This practice not only wastes a valuable resource but also contributes significantly to air pollution. When straw is burned, it releases carbon dioxide, particulate matter, and other harmful pollutants into the atmosphere, exacerbating global warming and respiratory problems in surrounding communities.

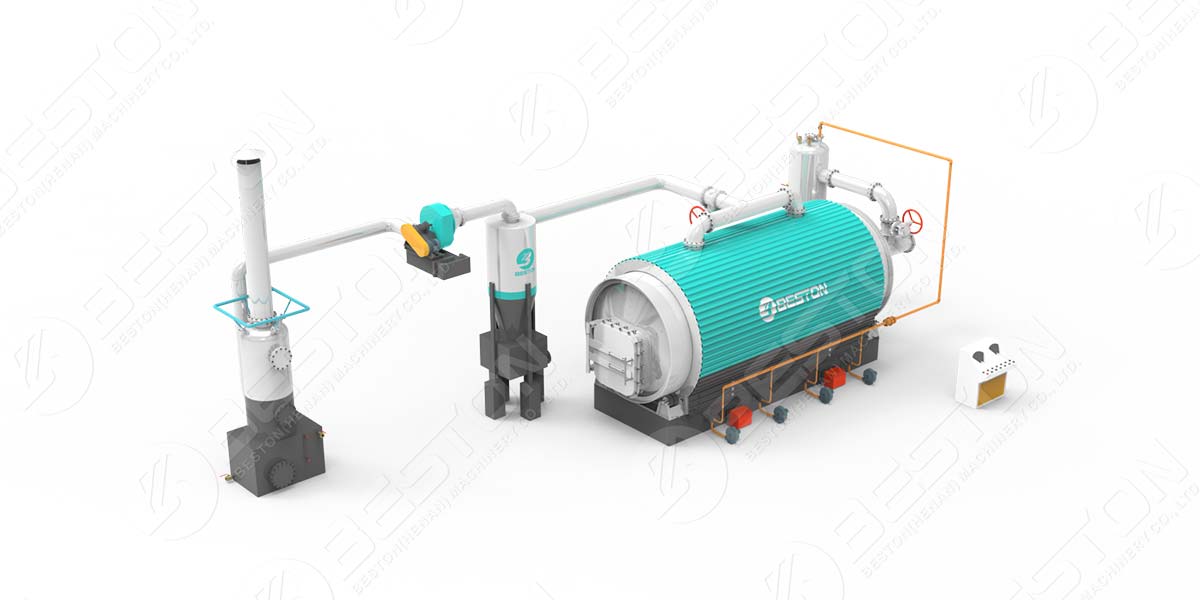

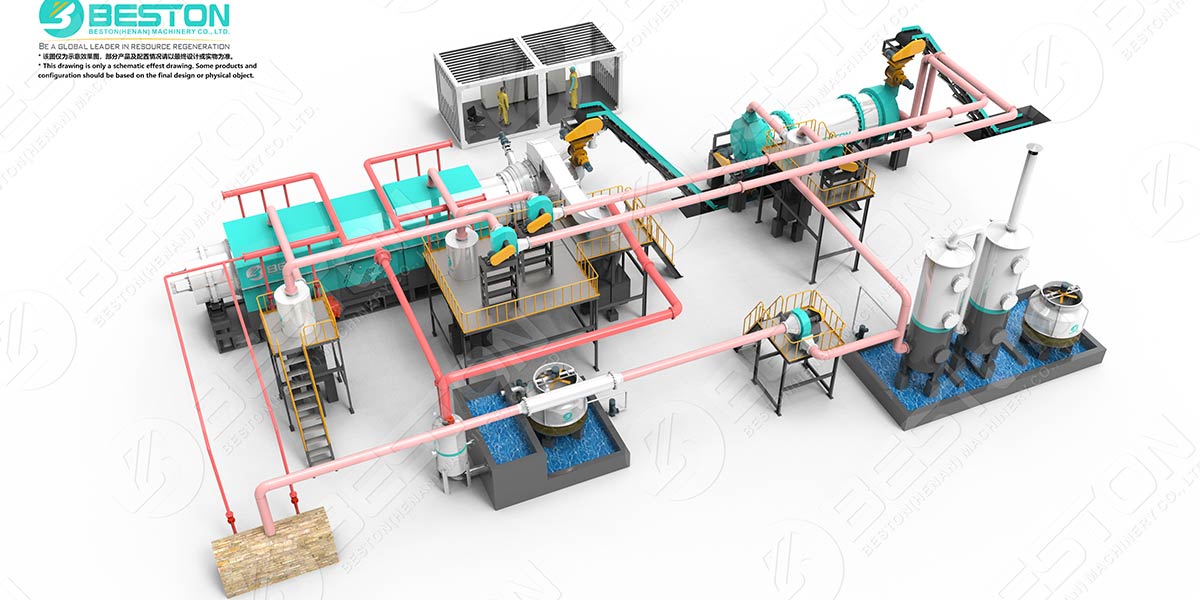

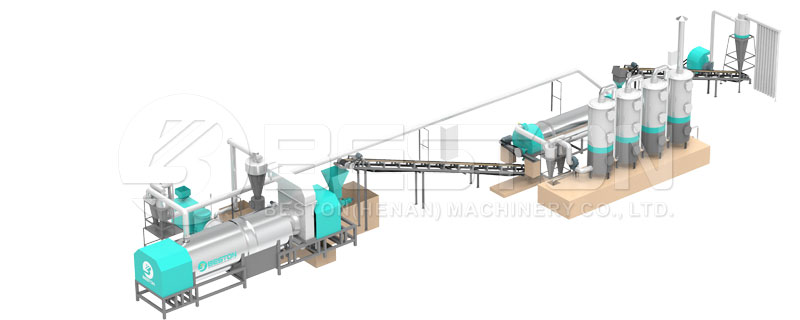

By converting straw into biochar through pyrolysis machine for biochar, this environmental burden can be avoided. The pyrolysis process is conducted at high temperatures in an oxygen-deprived environment, which decomposes the straw into biochar, syngas, and bio-oil. Importantly, this method produces minimal pollutants compared to open-field burning, significantly reducing harmful emissions. The resulting biochar can then be used for various purposes, including soil enhancement and carbon sequestration.

Carbon Sequestration and Climate Change Mitigation

One of the most compelling reasons for converting straw by straw charcoal machine is its potential to sequester carbon. When straw is converted into biochar, a large portion of its carbon content is locked into a stable form, which can remain in the soil for centuries. This process not only prevents the release of carbon dioxide into the atmosphere but also helps mitigate climate change.

Biochar’s ability to store carbon makes it a key player in the global effort to reduce atmospheric greenhouse gases. By integrating straw biochar into agricultural systems, carbon sequestration can be scaled to mitigate the impacts of climate change. In fact, biochar has been recognized as a powerful tool for achieving carbon neutrality, allowing industries and countries to offset their carbon emissions while promoting a sustainable circular economy.

Economic Viability and Revenue Generation

The economic advantages of converting straw into biochar go beyond the environmental and agricultural benefits. A biochar machine offers a potentially profitable venture, especially in regions where straw is abundant. By converting agricultural waste into high-value biochar, farmers and businesses can generate an additional revenue stream.

Furthermore, the by-products of the pyrolysis process—such as bio-oil and syngas—can be used as energy sources or sold to the energy market. This diversification of income can help offset the initial costs associated with purchasing and operating a biomass pyrolysis plant. As demand for biochar increases in agriculture, environmental remediation, and carbon credit markets, the long-term profitability of biochar production becomes increasingly evident.

In many regions, governments are providing incentives for sustainable practices like biochar production, including subsidies, tax breaks, and carbon credits. These incentives can significantly lower the cost of setting up a biomass pyrolysis plant and increase the financial viability of biochar production, making it an attractive investment for those looking to capitalize on green technologies.

Soil Improvement and Agricultural Benefits

The use of biochar as a soil amendment is another significant advantage. Biochar improves soil structure, increases water retention, and enhances nutrient availability, which in turn boosts agricultural productivity. Straw-derived biochar, in particular, has shown to be highly effective in improving soil pH, aeration, and microbial activity, which are vital for healthy plant growth.

Biochar’s porous structure helps retain moisture, making it especially beneficial in regions prone to drought or water scarcity. It also facilitates the slow release of nutrients such as nitrogen, phosphorus, and potassium, which are essential for crop growth. As a result, farmers can reduce the need for chemical fertilizers, which are costly and contribute to soil degradation over time. The long-term benefits of biochar include improved soil fertility and reduced dependency on synthetic agricultural inputs, promoting both ecological and economic sustainability.

Additionally, biochar has been shown to reduce soil erosion and enhance the resilience of crops to extreme weather conditions. Its ability to bind with heavy metals and toxins in the soil also helps to remediate polluted land, improving soil quality for future agricultural use. To learn more about biochar applications, please visit: https://www.bestongroup.com/