Over the years, manufacturers of rice and farmers generally have tried to find the perfect way to utilize rice husks. In the end, it ended up being accumulated waste and a polluter of the environment. But when the appropriate technology of the carbonization process came to be, rice husks finally were able to be put to good use by making them into charcoal through high-temperature pyrolysis, sulphur release, smoke discharge and charcoal enrichment. On top of this, it is also a good raw material for making charcoal. Here to know rice husk charcoal making machine.

Features Of Rice Husk That Make It Difficult To Dispose Of

Rice husk has a very hard surface with a high silicon content. This makes it very difficult for it to be decomposed through fermentation and be converted into fertilizer, unlike other crops.

It contains very small density in its bulk and as a result occupies a large space unnecessarily.

It cannot be disposed of through burning it directly because of environmental pollution regulations.

This has proved to be a very big challenge to planting and rice processing enterprises and hence the idea of using rice husks to make charcoal came into being. This way, the husks can be recycled and put to good use through the rice hull carbonizer. More information on the palm kernel shell charcoal making machine here.

How It Is Done

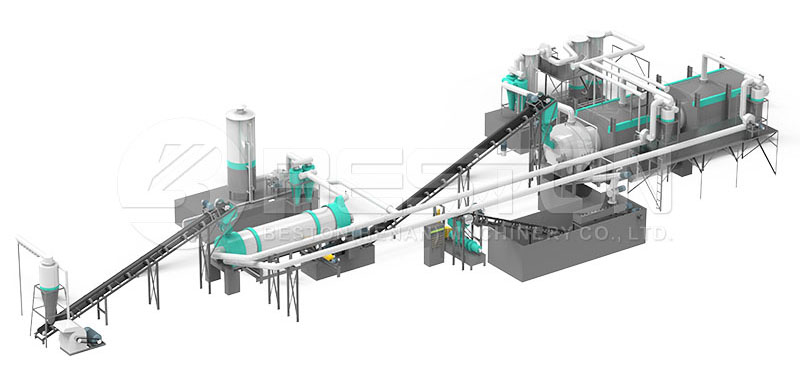

The raw materials involved in this process include rice husk, sugarcane bagasse, wood waste, agro waste, crop stalk, bamboo and other similar types of wastes. They should always have a moisture content of less than 12% and a width and height of less than 6mm.The rice husk to charcoal carbonator is a very powerful machine that combines these different types of waste under high temperature and pressure to form a high-quality energy product.

The rice hull carbonizer is automatic. On top of the charcoal carbonization furnace, there is a feeding system. This is where the process starts. The rice husks are put in the feeding system by the conveyor belt, they are then sent to the carbonization furnace for charcoal which is always continuous via the same feeding device.

After this, the material is arranged uniformly inside the internal feeding device. When they reach the required level, the feeding machine stops feeding. Through an ignition device inserted through the bottom of the bottom point of the charcoal furnace and into the carbonizer, the material will be fully burnt. The ignition device is then turned off and extinguished.

Then turn on the blowing 1 to suitable speed followed by the blowing 2 until the concentration of smoke in the burner has reached the burning point. Adjust the blowing 2 to get the suitable temperature for the process. At this rate, the machine will be operating automatically be feeding until the required level.

Advantages of The Rice Hull Charcoal Making Machine

The rice husk to charcoal carbonization machine is very energy efficient as it uses a small amount of energy. Get biomass pyrolysis plant costs here.

The carbonization furnace is made from the latest technology and carbonizes the rice hull is carbonized completely. It makes sure that the rice husks will not be burned during the process making sure that the final product is high-quality charcoal with very neat shapes.

The machine has flue gas cool and purification systems which ensure that no smoke is emitted into the environment. It has the modern water filter dusk collection system to ensure that all dust and harmful substance is filtered.

The machine can be designed according to the consumer’s specifications.

Final Products

Biomass charcoal which has a wide range of applications today is the main product obtained from this process. It can be used as a natural fertilizer as opposed to using chemical fertilizer because its components are harmless.

It can be used as fuel in cases of barbecue because of it has no negative effects on the environment eg.pollution.

Its high calorific value makes the carbonized rice husk good for use as fuel in industries.

Flue gas generated through this process can be recycled in the fire pot to avoid the problem of pollution.

Conclusion

The charcoal making machine has not only come to solve the issue of disposing of rice rusks in the most appropriate way, but it also utilizes other readily available waste materials. The briquettes made from this process are of very high quality and the carbonation process can further convert the husks into activated carbon. The machine makes use of the latest technology and most importantly, it is environmentally friendly.