Plastic pollution is one of the most pressing environmental issues of our time. The world generates millions of tons of plastic waste annually, and finding sustainable solutions to manage this waste has become imperative. Plastic pyrolysis equipment has emerged as a groundbreaking technology that offers a way to convert plastic waste into valuable resources while mitigating the environmental impact. In this 1500-word post, we will explore plastic pyrolysis equipment, how it works, its environmental benefits, economic viability, and its role in revolutionizing waste management.

1: The Plastic Pollution Crisis

To understand the significance of plastic pyrolysis equipment, we must first comprehend the scale of the plastic pollution crisis. This chapter discusses the environmental hazards posed by plastic waste and the urgent need for effective solutions.

2: Plastic Pyrolysis

What exactly is plastic pyrolysis, and how does it work? This chapter provides a comprehensive overview of the pyrolysis process, detailing the types of plastics that can be processed and the products it yields.

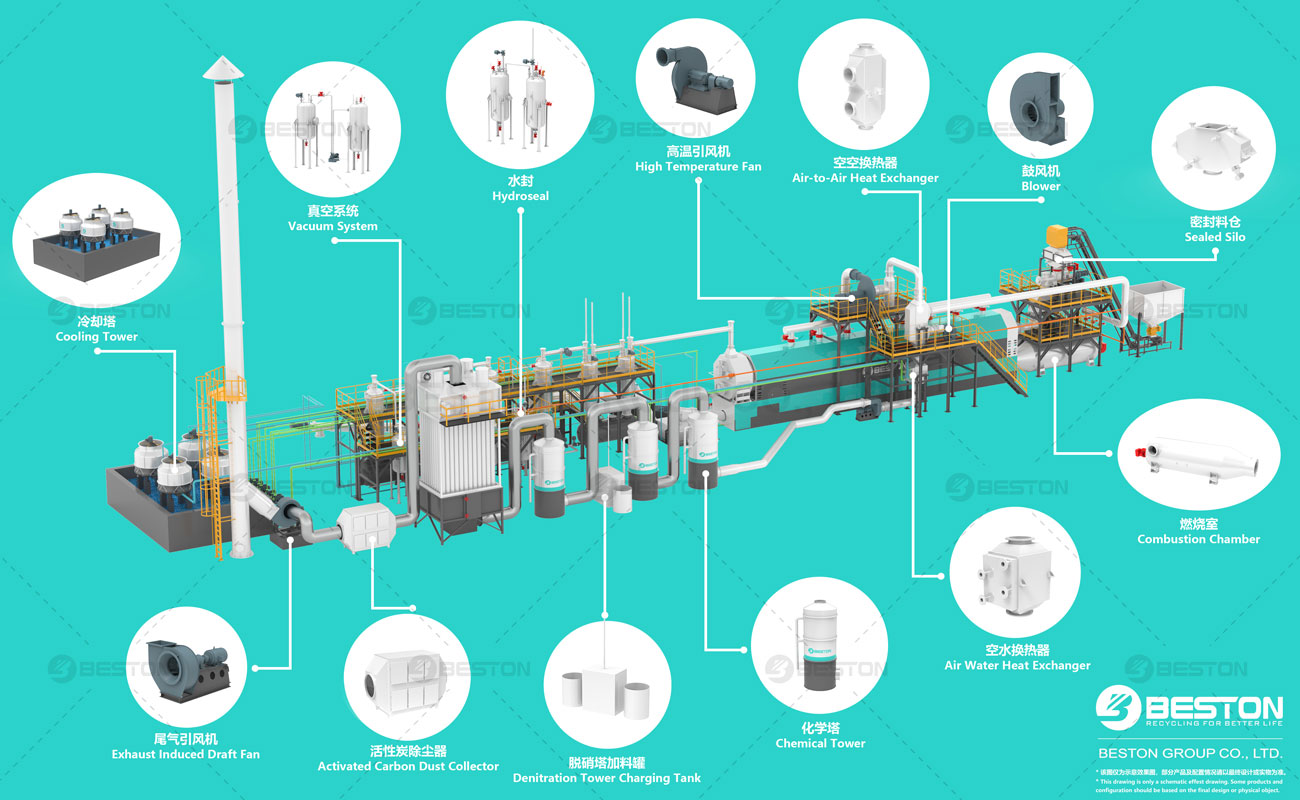

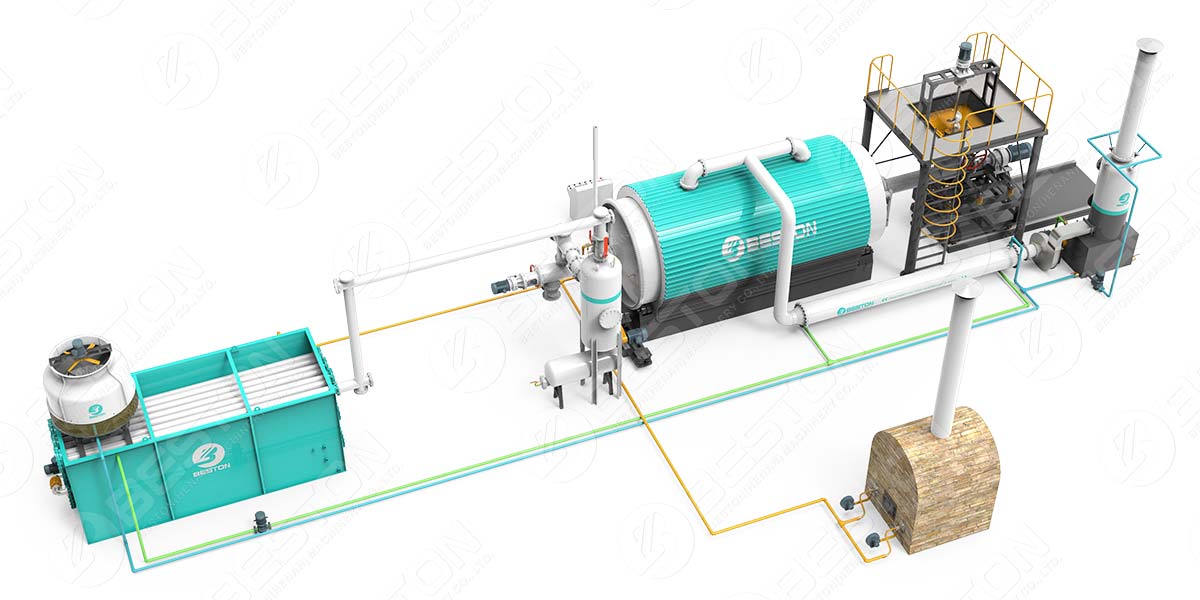

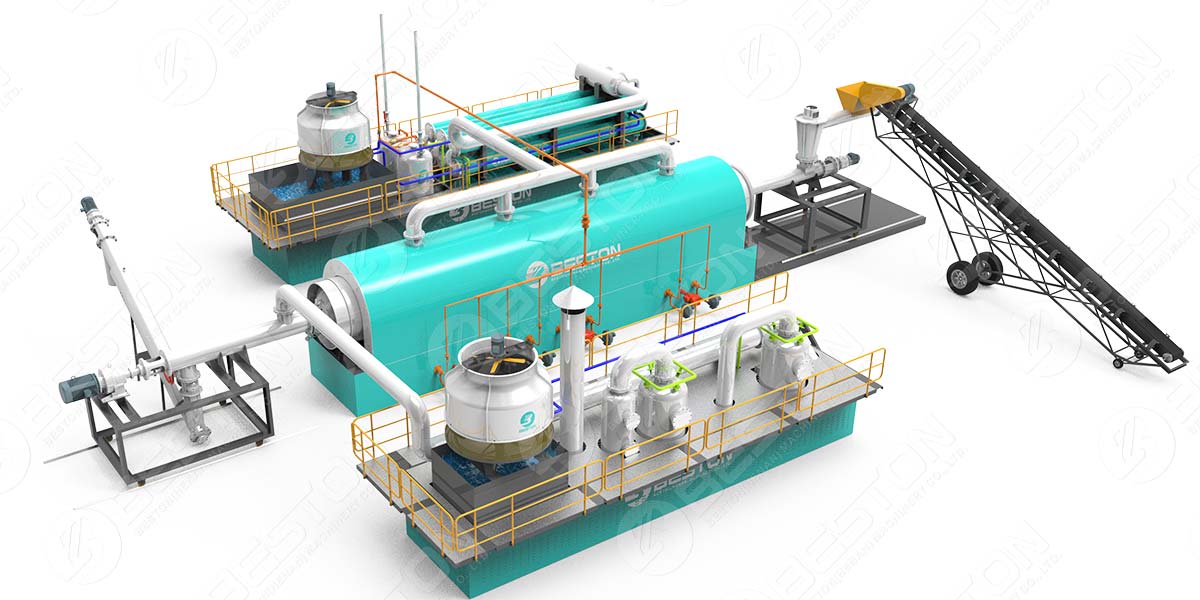

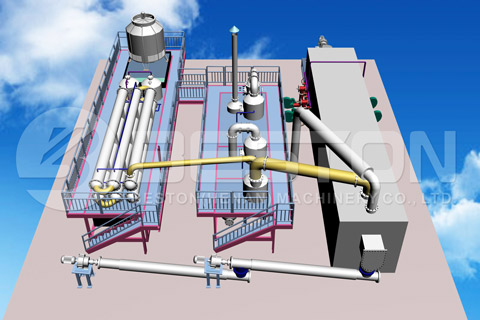

3: Types of Plastic Pyrolysis Equipment

Plastic pyrolysis equipment comes in various forms and sizes. This chapter explores the different types of equipment available, from small-scale units to large industrial systems.

4: Environmental Benefits

One of the primary drivers for adopting plastic pyrolysis technology is its environmental impact. This chapter delves into how these machines contribute to reducing plastic waste, curbing pollution, and lowering carbon emissions.

5: Economic Viability

Investing in waste pyrolysis machine requires a financial commitment. This chapter discusses the economic feasibility of such investments, considering factors like operating costs, potential revenue streams, and government incentives.

6: Regulatory Landscape

Navigating the regulatory framework is essential for plastic pyrolysis plant operators. This chapter provides an overview of relevant regulations, permits, and compliance standards.

7: Success Stories

Real-world case studies highlight the practical benefits of plastic pyrolysis equipment. This chapter presents success stories of businesses and organizations that have successfully implemented this technology.View the pyrolysis plant cost estimate from manufacturers.

8: Future Prospects

As technology evolves, plastic pyrolysis equipment is becoming more efficient and versatile. This chapter explores emerging trends and innovations, such as advanced feedstock options and improved product quality.

9: Community Impact

Plastic pyrolysis plants can have a positive influence on local communities. This chapter examines how these facilities create jobs, support recycling initiatives, and contribute to a cleaner environment.

10: The Path Forward

In conclusion, plastic pyrolysis equipment represents a transformative solution to the plastic pollution crisis. Its ability to convert plastic waste into valuable resources while mitigating environmental harm is a testament to its potential. As the world seeks sustainable waste management practices, plastic pyrolysis equipment offers a path forward, reducing waste, curbing pollution, and fostering economic growth. By embracing this innovative technology, we can revolutionize our approach to plastic waste, preserving our planet for future generations.