Millions of tyres are dumped each year in the landfills. This not only creates a nuisance but it is also harmful for the environment. A lot of chemicals are used for making tyres in addition to the rubber. When these waste tyres lie in the landfills, there is a possibility of these harmful chemicals leeching in to the groundwater below and pollute the water supply. This is the reason that the use of tire pyrolysis plant is gaining a lot of popularity for recycling the waste tyres.

One of the biggest advantages of this system is that with the help of pyrolysis technology, it is possible to get fuel oil from waste tyres as well as plastics. The raw materials needed for operating this waste pyrolysis machine is very cheap as these raw materials are useless to people. In other words, it is a highly profitable business especially when there is no shortage of raw material.

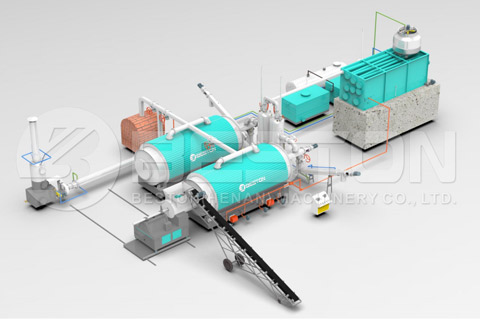

As far as the final products produced in a pyrolysis plant is concerned, these include fuel oil, carbon black, steel wire and gas. The main product generated by the recycling machine is the fuel oil which is widely used in industries and has great commercial value. Around 45 to 50% of the amount of recycled scrap tyres is generated in the form of fuel oil. This oil can be used in cement factories, ceramic factories, boiler factories, central heating, glass factory and power plants among others. Now we have this kind of advanced waste pyrolysis machine. You also can compare tyre pyrolysis plant price among different manufacturers.

Around 30 to 35% of the recycled scrap tyres is generated in the form of carbon black. The carbon black generated through pyrolysis process is much cheaper as compared to the carbon black produced from petroleum. Carbon black is used as a raw material in a variety of industries.

Around 10 to 15% of the initial raw material is produced in the form of steel wires. The steel wires can be easily obtained once all the raw material has been converted into fuel oil and carbon black. Around 5% of the raw material is generated in the form of gas (around 4% methane content) that can be used for heating as well as for various other purposes.

The biggest advantage of pyrolysis process is that it results in 100% recycling of waste tyres. This technology produces highly valuable materials that are used in a variety of industries. There is no other way to get rid of waste tyres in an environmentally friendly way.

Overall, there are a number of advantages of pyrolysis technology. It is environmentally friendly and the tire recycling plant cost is affordable. It is a profitable business that gets rid of the tyres in the landfill. There are a number of other advantages of waste tyre pyrolysis recycling system. Here is a list of some of those advantages of tyre oil machine. Know about the advantages from a reputable manufacturer.