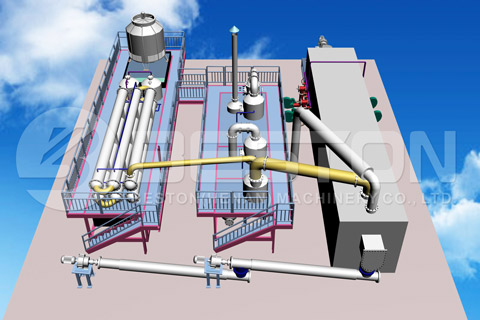

A solid waste pyrolysis plant (Planta de pirólisis de residuos sólidos) is an amazing investment for businesses as it is effective, proven, and safe to use all wrapped into one great package. For businesses that are trying to find cutting-edge tech for all of their long-term needs, it is time to start here.

A solid waste pyrolysis plant is going to be an incredible fit and will look the part.

Here is a closer look at what this type of plant is all about and why it works so well.

High-Powered

The amount of power that is going to be utilized by this machine will pale in comparison to the power it generates throughout the day. This is the real charm of a solid waste pyrolysis plant (planta de pirólisis)and why it works so well.

It is going to take all of your solid waste and make the process look like a breeze. This is great for both the short and long-term.

Processes Solid Waste

The solid waste that is going to be on-site will be pushed through this plant. The plant is then going to have internal mechanisms to continue to process the waste and convert it.

The simplicity of the process is why this plant has become a popular option for businesses.

More and more are looking towards this as a viable option due to how effective it is in generating results. You are going to take up less time and it is going to continue to pump out value as it works in the background.

Quick

The speed at which things are going to be done is what makes this a great fit.

The plant is going to take solid waste that is being pushed through and process it in seconds. The power output can be amazing depending on which type of plant you set up on-site. However, it is going to be rapid and is going to be faster than most other solutions that are readily available to you.

Anyone that is serious about using a high-powered setup will want to have this machine (planta de pirolisis de lodo aceitoso) in mind. It is going to make a difference.

User-Friendly

The purpose behind using this is to make sure it speeds things up. This is what the average business will want as they are trying to handle solid waste. However, the beauty of a plant such as this is seen through how user-friendly it is.

This is great for those who are trying to set up a straightforward solution that is going to churn out results as soon as it is put to use.

These are the qualities you are going to see from a solid waste pyrolysis plant and that’s what’s going to make it stand out. You will begin to appreciate how effectively it works and how easy it is to use throughout the day.

Businesses that are trying to take the next step with their setup need to have a look at this https://www.bestoneco.com/. It is going to provide tremendous versatility and will be a joy to use.