With the environmental challenges that the human race faces, it is important that we make use of every resource that we have prudently. This means putting to good use every kind of resource that we have, even the waste products. In this regard, when it comes to coconuts, the waste coconut shells which tend to be very difficult to dispose of can be used as a resource.

The rigidity and durability of the material mean that it can last quite long before decomposing completely. When you consider the amount of coconut shell waste that is produced as a result of small and large scale coconut process, you can appreciate how big of a problem managing coconut shell waste can be. You can learn something about charcoal production plant here.

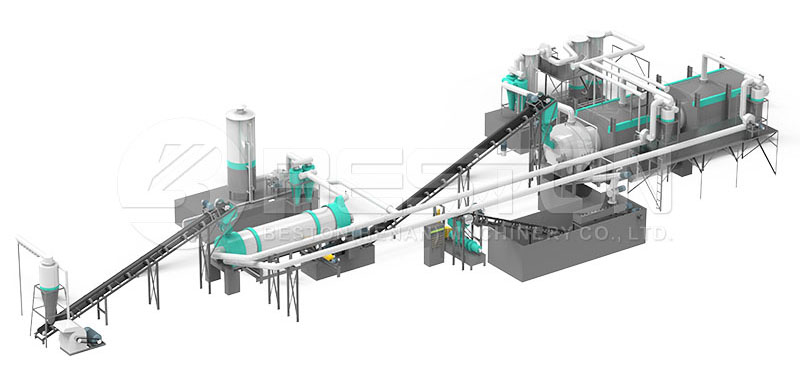

However, when this waste is converted to a resource that has utility and can generate an income, the entire process of coconut shell waste management becomes a far easier and profitable endeavor. The coconut shell charcoal making machine is amply capable of doing this. These machines/plants turn the otherwise waste biomass into a material with utility – charcoal and other useful products.

Coconut Shell Charcoal Making Machine Processes

The first step in turning the shells into charcoal is to crush and dry and dry them. The crushing process is meant to reduce the shells into small particles that are easy to process. As such, the shells are crushed by a machine and reduced to 50mm pieces. As for the drying, reducing the moisture content in the shells to less than 20% makes it easy to process the shells. To this end, they are fed into a dryer.

After crushing and drying, the material is fed into the carbonization chamber/furnace. Herein, the shells are taken through the pyrolysis process, where they are heated to a high temperature in a somewhat oxygen-free environment. Consequently, the organic material is converted to coal. Other by-products of the process include combustible gas.

The charcoal is taken through a cooling system where the heat exchange system helps to cool the charcoal to as low as 30℃. The heat extracted is returned to the carbonization chamber to heat the next batch of shells. On the other hand, the gas is taken through a dedusting system, where all the dust is collected from the combustible gas. At this point, the gas can be collected in readiness for selling or it can be used as an energy source for running the carbonization chamber.

Products And Their Uses

As mentioned above the process yields the desired charcoal. This product can and is used for cooking (think of barbecuing), fuel for furnaces, or raw material in the production of active carbon. The gas produced, as mentioned above, can be sold or used in the carbonization of subsequent batches of shells. Finally, the process produces tar and wood vinegar. These products have utility in the industrial sector.

A High-Quality Coconut Shell Charcoal Machine

The effectiveness of this process as a business venture and with regards to producing high-quality products is highly dependent on the kind of machine you have. To this end ensure that the power consumption, production capacity and yield, and the construction quality of the machine meet your standards and your expectations (keeping in mind the availability of shells).

We also have other biomass charcoal machines for sale, such as palm kernel shell charcoal machine, wood carbonization plant and so on. You can contact us to get more information.