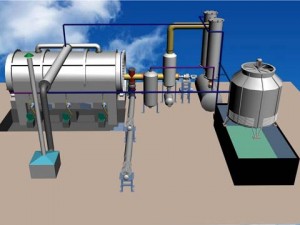

Plastic pyrolysis is a brand-new technology that is revolutionizing the way recycled plastic is processed and handled. There is essentially no limit to the capabilities of modern plastic pyrolysis machine for sale, essentially all plastics can be broken down and recycled back into oil. The science behind this technology is that it mimics the natural geological processes that turned biological material into oil over millions of years. With intense heat and pressure, and because plastics are a lot closer in a chemical sense to oil to begin with, this process can be accelerated tremendously. Here are the four most important things to remember about making oil from plastic waste by the pyrolysis method.

1. All plastics can be used as feedstock material

Absolutely all waste plastics, no matter what kind of polyethylene, polyether, polyacrylamide can be used as feedstock for the plastic pyrolysis process. There is no need to separate plastics by recycling type. The only effect that the plastic composition has on the end product is the length of the hydrocarbon chains, but it will only effect the distribution of these lengths. Oil that is obtained by the pyrolysis process has to be fractionated and processed like any other oil, so these effects may affect the end price that is paid for the oil, but it will go through the same processing procedures in any case.

2. Plastic additives are acceptable

The same also holds true for any dyes, plasticizers, or crosslinkers that may be present in the plastic feedstock, these compounds are broken down into hydrocarbon materials just like the plastic itself. These compounds may leave behind some trace elements such as nitrogen or chlorine, but these will be eliminated when the oil is fractured in processing. The recovery of these elements may even lead to additional profits.

3. Pyrolysis oil is chemically identical to natural oil

Since plastics are produced from oil in the first place, when they undergo the pyrolysis process of Kingtiger Group Pyrolysis and return to being hydrocarbons, the oil that is produced from this process is chemically extremely similar to the natural oil that was used to make the plastic in the first place. In fact, plastic pyrolysis oil is particularly valuable, since it contains high levels of the oil components that are the most useful for plastic production and these oil components are much more valuable that those used to produce natural gas or asphalt. If you want to get more pure pyrolysis oil, you can distill it by waste oil recycling machine for sale from Kingtiger environment technology company.

4. Pyrolysis takes time

Even though the natural geological processes are vastly accelerated by the application of intense heat and pressure, these processes can still take quite a while, because the chemical reactions involved happen very slowly. Another factor is that the longer you keep your plastic feedstock in the pyrolysis process of plastic to oil machine, the higher quality your end product will be.

So with all that said, are there any downsides to plastic pyrolysis processes other than the time that it takes. The primary one is that it requires a lot of energy to power this process because of the heat and pressure required, so it should be done in areas with inexpensive electricity. There is another type of cheap waste tyre oil extraction machine from Kingtiger.