If you need to make large quantities of egg trays you will want to invest in an egg tray machine. This machine produces egg trays fast and it will increase your productivity so you can make more money quickly. If you want to make your business profitable, you need to have an egg tray making machine project report for help, so that you can find the egg tray machine that is the best choice for your business.

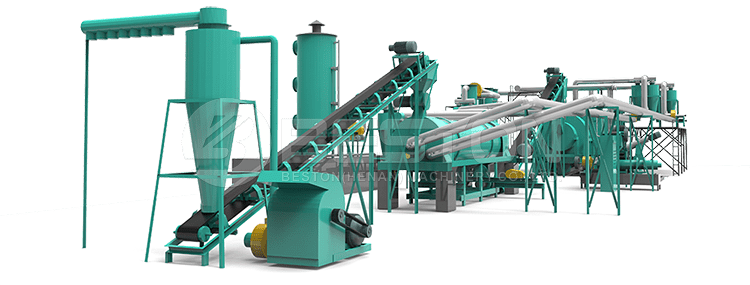

The egg tray machine is economical to run since it uses waste paper. The waste paper is very cheap and it is also good for the environment since the paper is recycled. The machine can turn the waste paper into many different types of products including egg trays, egg cartons, shoe trays, fruit trays, and more. More than that, the egg tray machine is eco-friendly. There is no pollution during the whole process.

Since the machine is cheap to run, a business will find that it is easy to maximize its profits by using this machine since it can make so much money for such a cheap price. This machine allows investors to enjoy a huge return on their investment so they can pay the machine off quickly. As you know, there is manual, semi-automatic, and fully automatic egg tray machine for sale on the market. The first thing you need to do is to find a suitable egg tray machine.

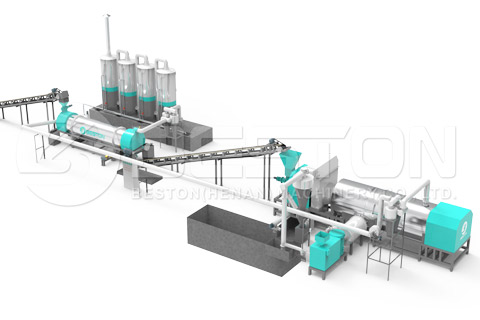

The machine is very easy to operate and it also produces quickly. Customers can choose from a variety of models and the machine can also be customized so the customer gets exactly what they are looking for. In order to have a machine customized, you need to know how many egg crates you need to make each hour. Once you have this number figured out you can go ahead and begin to work with the manufacturer. The manufacturer will help you choose the machine that will be the best fit for your business and they can help ensure that you get exactly what you need.

The egg tray machine is made with the best materials and it is designed to work for a long time without having any issues. Each machine also comes with spare parts so you won’t have to deal with a long period of downtime when you need to work on the machine.

Each machine can be customized which means you can get exactly what you want with this machine. Except for egg tray machine, the egg carton machine is also very popular. The customization process is easy and the manufacturer will ensure that you get just what you need to get the most out of your machine.

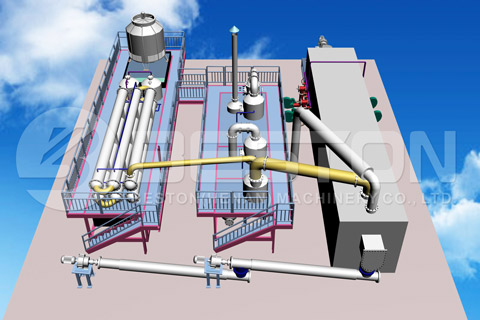

Once you get your machine you will greatly benefit from the on-site installation offer. The manufacturer will set up the entire machine for you so you won’t have to do anything except start using it. You also get to benefit from free training for your workers. You will also get technical service for the life of the machine. Support is available around the clock so you always have the support when you need it.

The paper pulp molding machine is a great investment in your business. This machine will give you a great return on your investment and it is something that you will want to buy for your company.