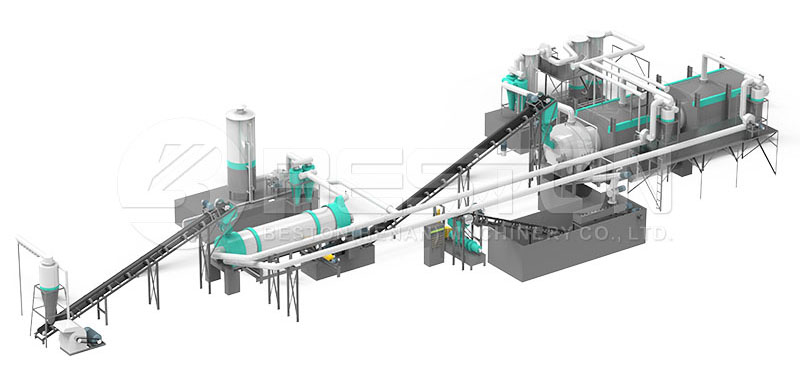

The rubber powder machine is able to process rubber products such as waste tyres into a rubber powder at a standard room temperature. This production line is typically utilized to recycle 550 to 1200mm waste tyre. The product produced is a 5 to 30 mesh-rubber powder from waste tyres. When processed using a rubber grinder, the end product can result in a 40 to 120 mesh-fine type of rubber powder. Beston offers different models to satisfy your demand. View https://BestonTurkey.Com. Once processed using this recycle line, the steel can be separated completely while fibers are separated up to 99 percent or more.

Features Of Rubber Powder Machine:

•The process granulated tyres into an extremely fine based rubber powder while fiber and steel is recycled completely at an ambient temperature before processed by pyrolysis plant.

•The purity of this rubber powder is 99 percent.

•Small space, tight construction and a basic technique flow.

•The process uses low energy consumption and offers a favorable performance to cost ratio.

•The process offers auto-immunization and requires very little labor requirements. View this page to know more about process: http://tyrepyrolysisplants.net/tire-recycling-equipment-for-sale.html.

•Long service times, high output and a unique design.

•This production features a dust remover which means the equipment does not cause pollution meaning there are no fibers or fine dust that lands up in the air. The process matches up with environmental requirements required by the government.

Besides, the rubber can be turned to oil by pyrolysis machine. Read this page to know more: https://bestonturkey.com/rubber-pyrolysis-plant/.

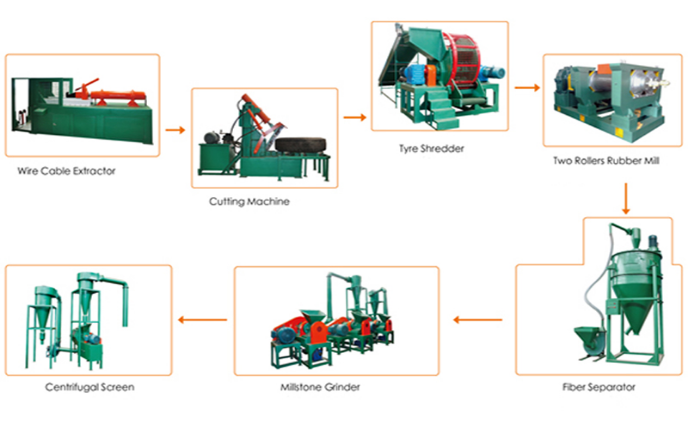

1.The initial step involves cutting the tyres using the ring-cutting machine that cuts the tyres to the sidewall and the inner circle. Do you know continuous machine which is more convenient?

2.This is followed by the use of the tyre-strips cutting machine that cuts the sidewalls of the tyres into long strips.

3.The next step involves the tire cutting machine that cuts the long strips up into blocks.

4.A steel-wire separator processes the inner circles and separates it into tyre rubber and pure steel.

5.The blocks of tyres are placed into the tyre crusher. These blocks are then grinded up into 8 to 10 mesh-rubber powder. The screen positioned underneath the vibrating-screen that sends the 8 to 10 rubber-powder onto a conveyor which transports the product to a magnetic-system. In this system thin steel inside the rubber tyre is cleared away and the rubber-powder is sent onto the small vibrating-screen and through this particular screen the end result is a pure 30 mesh rubber powder. Besides, waste tyre can be converted into oil by tyres pyrolysis plant.

6.In the fourth step parts of the rubber that do not reach the 8 to 10 mesh rubber-powder are sent to the large vibrating-screen to a large conveyor that sends the product to the tyre crusher. The product is crushed and then sent back the beginning part of step 4 until such stage that it has reached an 8 to 10 mesh rubber-powder.

Tyres come in two types, the first is a steel tyre while the other is a fiber tyre. If the main part of a tyre is made up of steel, the first 6 steps are sufficient. However, if the tyre is mainly made up of fiber, a fiber separator is needed in order to separate the tyre rubber-powder from the fiber in order to reach a pure-rubber powder. We Beston Machinery are pyrolysis machine manufacturer. We provide different machines, like shredder, pyrolysis plant, charcoal machine, etc. Go on https://bestonturkey.com/biomass-pyrolysis-plant/ for learning more info. If you are looking for a reliable supplier, visit us.