The manufacturing of asphalt often requires large China asphalt mixing plants, ones that are typically stationary. These are large-scale operations, capable of producing as much as hundred tons or more of this material every single hour. Asphalt is a combination of aggregates and bitumen, mixed together at high temperatures. Depending on what country are in, you should have access to ample supplies of bitumen, gravel and sand that will be necessary to make the asphalt. The only thing left is to purchase the best stationary asphalt batching plant that can keep up with your company’s demands.

How Is Asphalt Made Within The Batching Plant?

The process by which it is made can happen in a couple of ways. The most common is through a hot asphalt batching plant. They will increase the temperature of the bitumen to around 300 degrees Fahrenheit. It must remain at this temperature once it becomes viscous and is transported to its destination. You will often see mobile asphalt mixing plant producing this on the road, something that can be much more convenient. However, if your main objective is to purchase a stationary asphalt batching plant, this is going to help your business save money and keep up with all of the contracts that you are acquiring.

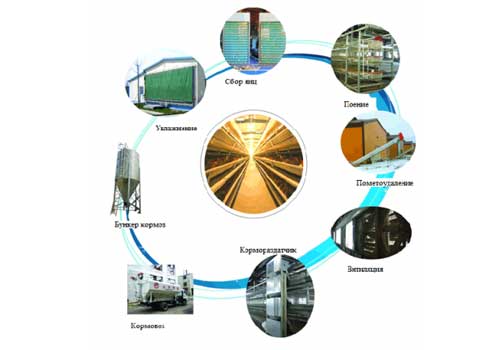

Making Asphalt From Start To Finish

The process itself is straightforward. There is aggregate material and bitumen that will come together in a drum mixing plant where it is heated. Once this is done, it will be placed into an area for weighing in mixing, and then moved to a hot storage bin. These are very large, allowing large trucks that will take the viscous material to different destinations, all the while maintaining its temperature. It then will be poured where it needs to go, allowing asphalt mixing plant manufacturers and businesses that pave roads to complete their projects.

Is It Easy To Find A Deal On One Of These Batching Plants?

It’s easy to find companies in countries like China that make these on a daily basis. This country in particular has some of the most high-tech businesses making these products every day. You can get quotes from these businesses, find out how much they are charging for the batching plants for asphalt that they have for sale. You can ask about the features of each one, how long it will take to ship, and also how long it will take to set up.